3.73:1 gears? Why not in the 4 series? Edit guess 800+hp won’t matter what gears

Now that you've done a T400, have you thought about a 4L80e ?

From what I've seen, a 4L80e in rebuildable shape is not expensive, but most shops want $2000+ to rebuild one.

Rick, I decided on 3.73 rear gears for a couple reasons: 1st, when I had the first set of heads on the motor which I don't believe are quite as good as the heads I have now, it made 802 ft/lbs of torque@4,200rpm with 715 ft/lbs in by 3,000rpm. With a 4.75" stroke and a 4.6" bore, I really don't think I need 4.10 gears with a 2.48 first gear in the trans. I believe the engine has plenty of torque to get the car off the line with 3.73 gears. If I had a powerglide trans with the higher first gear like many other drag racers at this power level use, that would likely call for 4.10 gears with this combination. And BTW those dyno numbers were also with a smaller camshaft. I now have a camshaft that will be increasing the lift at the valves by .125" more than the camshaft I had in the engine when it was run on the dyno. But at the same time, the new cam has a dur@.050 that's very close to the duration of the old cam, ( with only a 6 degree increase). That dur@.050 is only 274 degrees which is a fairly short dur@.050 for a 632cid engine.

The original cam having a 268/271 dur@.050 had the power peak@5,900 rpm so I believe 4.10 rear gears would be a little bit of a mismatch for the cam I'll be using. If I were to use a 284 dur@.050" I think that would call for 4.10 gears. But time will tell. If I'm wrong about that, then I can always do a ring& pinion gear swap if need be. But my thinking is this: How many well matched street/strip cars have you seen, owned, or been in with 4.10 rear gears which had a power peak@ merely 6,000 or 6,200 rpm? I believe most well sorted out cars with 4.10 gears have engines with power peaks of at least 6,800-7,000 rpm.

Second, in addition to that, I also didn't want the engine to be reving@3,800rpm at 70 mph on the highway which it would be with 4.10 gears and a TH400 trans. The 3.73's should keep it@3,200 rpm at a 70 mph cruise speed. I can live with that, because I have before for 6 years with the old Vette I used to have. But again, time will tell. Thanks for the question.

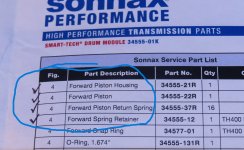

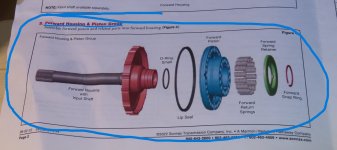

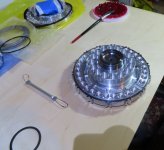

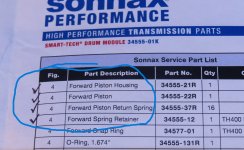

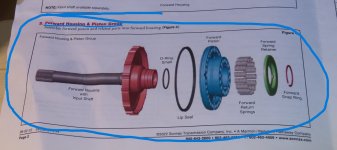

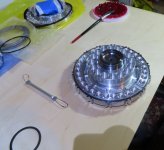

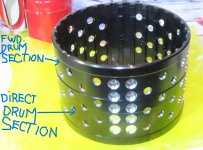

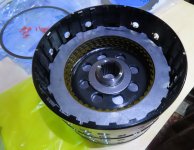

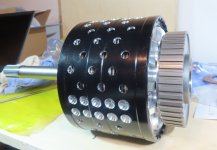

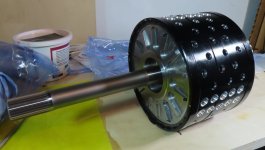

Beth, I'm not yet done with this TH400 build. Those photos are just the beginning stages. I still have to assemble the rear gear train, modify the pump, ( although a minor modification) and install everything into the new case which also includes the intermediate clutches, and the center support. So I'm not done with this project just yet. These are really baby steps cuz I'm still a novice at this trans building thang.

Anyway, as you likely already know, it's often said that a 4L80 is like a TH400 with an O\D gear added. I'm not sure, but I think the 4L80 case is slightly bigger than that of the TH400, ( which BTW might very well be due to the O\D gear). I already have a TH400 in the car now, ( which is only rated for about 125 HP less than what I expect the engine to make) and it was such a tight fit for me to install that TH400 into the car, that I had to literally take a 20 lb sledge hammer to "massage" the floor tunnel to get the trans to fit while the car was on my brother's lift, ( another reason why I went with a Reid SFI approved case, since I won't need a trans shield, and there's no way I can fit a trans shield in the car).

So my guess is that I'd have to cut the entire floor tunnel out of the car, and get a buddy of mine who does body work, to fab up a whole new, bigger floor tunnel for me in order to fit a 4L80 housing case. That's something I'm not willing to do merely to have an O\D gear. Another thing is that I've had two transmissions in the past in other cars with less power, ( 475HP and 530 HP) with overdrive gears, and I blew the O\D gears in both those transmissions from merely street driving, (the last one I blew the O\D in on the highway late at night at 140 mph). So I'm not a huge fan of O\D gears. I guess I'm just too rough on my cars and on transmissions to have one.

Anyway I don't expect this Chevelle of mine to be a smooth riding car by any means. With a solid roller cam having .817" lift at the valve, with one of the most aggressive cam lobe profiles that the late great Harold Brookshire had designed, ( AKA "UDHarold") 810 lbs of open valve spring pressure, 2 1/8" primary tube headers with a 3.5" diameter exhaust, and straight through mufflers without any baffles, and an engine that's chained to the frame of the car to prevent a motor mount failure from allowing the air cleaner to be pushed through the hood, as well as a spool in the rear end, I don't expect it to be the type of car that I'll be very concerned about having an overdrive transmission in. The car will probably rattle your teeth after a half hour drive. In fact, my buddy and fellow drag racer thinks I'm nuts for even having power steering in the car, ( IDK, maybe he's right). IDK how cheap or expensive it might be to rebuild a 4L80 as compared to a TH400, but at a power level of close to 900 HP and in a real heavy car like mine is, I don't think that any factory stock TH400 nor 4L80 nor even a factory 4L85 trans will hold up very long. So I know that I'd still have to modify any one of those transmission models. Thank you also for your question. I appreciate your interest.