I've got this hub that's been ground down on the end, for what reason I don't know. It'll work fine as is, but I want to add weld and grind to it's original shape. So, it's cast, it's got a thin parting line so it's not forged. I have 316T wire that I've used before for cast and it seems to work fine but never stress tested. My method is start the weld in one spot, get it hot, then work the weld. Thoughts?

Old Chevelles

Welcome to OldChevelles.com, built by Auto Enthusiasts for Auto Enthusiasts. Cars are not our only interests so please feel free to post about any subject the community might enjoy or you just feel you need to air.

We respect free speech and constructive dialogue however we don't allow threatening talk against members, nudity, or pornography. Threads are monitored and trolls are not tolerated.

This site is completely free and there are no costs. Please enjoy and provide feedback.You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Question for Molly.....welding

- Thread starter cheveslakr

- Start date

I have never welded with or heard of 316T. I have used 316L, but not on cast. The L stands for low carbon.

I prefer Inconel 625 for anything cast. Anyway, if the puddle looks good, go with it. It's just for cosmetic purposes.

I googled 316T & came up with 316Ti. Ti is titanium. I know that cast parts have lots of carbon content and titanium has a strong attraction for carbon forming titanium carbide which is a harmless compound.

I'll ask around at work today.

I prefer Inconel 625 for anything cast. Anyway, if the puddle looks good, go with it. It's just for cosmetic purposes.

I googled 316T & came up with 316Ti. Ti is titanium. I know that cast parts have lots of carbon content and titanium has a strong attraction for carbon forming titanium carbide which is a harmless compound.

I'll ask around at work today.

Silicon bronze is the preferred filler rod for cast iron. It's non-fusion. Inconel 625 or Haynes 25 for fusion welding cast iron. Must pre heat & post heat.

Looking at your part better now that I'm off work, and awake, looks like cast steel, not cast iron.

If it is indeed cast steel, just some good ole ER 70 or ER80 would be fine I think. 316 would be overkill. Any 3 series or "austenitic" stainless steel filler rod will have trace

amounts of titanium to control carbon migration issues. You want to control the carbon as it can make a brittle weld in the heat affected area and invite corrosion or rusting.

Looking at your part better now that I'm off work, and awake, looks like cast steel, not cast iron.

If it is indeed cast steel, just some good ole ER 70 or ER80 would be fine I think. 316 would be overkill. Any 3 series or "austenitic" stainless steel filler rod will have trace

amounts of titanium to control carbon migration issues. You want to control the carbon as it can make a brittle weld in the heat affected area and invite corrosion or rusting.

That's so interesting and thanx for the very complete explanation. The wire I've got is 316L, sorry was going off memory. I've got ER70 loaded in the machine now. How can you tell the difference in cast iron or cast steel. Is it color, or grain? To recognize it just from that little photo tells me it's obvious but if it's not in the part casting number, I have no clue. Is a rear end center section cast steel? It makes great sense that this suspension strut would be cast steel.

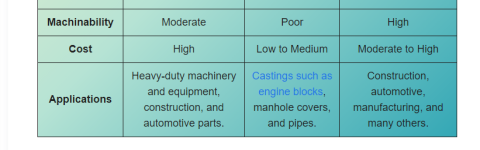

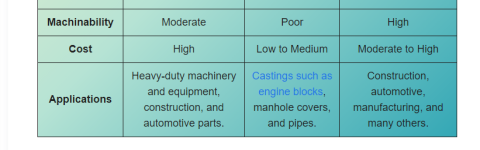

The 3 are described below.... cast steel x cast iron x steel

The 3 are described below.... cast steel x cast iron x steel

Attachments

kmakar

Janitor

That's so interesting and thanx for the very complete explanation. The wire I've got is 316L, sorry was going off memory. I've got ER70 loaded in the machine now. How can you tell the difference in cast iron or cast steel. Is it color, or grain? To recognize it just from that little photo tells me it's obvious but if it's not in the part casting number, I have no clue. Is a rear end center section cast steel?

The 3 are described below.... cast steel x cast iron x steel

View attachment 18774

Cast iron is very brittle, so in my opinion given it's part of the center section, I'd think it was cast steel.

Reminds me of and issue a client had with the cast iron feet on bar tables asking me to fix it and I never even attempted. When it snapped you could see the grains and there was no way I was going to try it.

Cast steel should "peel off" when you strike a corner while cast iron will break or shatter.

When broken, you can tell cast iron by the look of grain structure. Cast iron I believe is around 6% carbon. Picture a glass of hot ferrite in solution adding carbon until it's a saturated solution. You can't add more than 6%.

Cast iron has excellent compression/vibration qualities but no stretch or elongation. This is why vertical mill & lathe tables & engine blocks will be cast iron.

You said you had ER70 loaded in the machine. That tells me you are using a MIG or Metal inert Gas welder. 75/25 shielding gas I recommend. The only way you will know if things are going right is to look at the weld after your done.

The main thing to look for is porosity.

With a Tig I can see if there is a problem before I even add filler rod. The problem is contamination from something. I can usually tell from the color from the arc what is going on.

The first 3 rules of welding are clean, clean & clean.

Cast iron has excellent compression/vibration qualities but no stretch or elongation. This is why vertical mill & lathe tables & engine blocks will be cast iron.

You said you had ER70 loaded in the machine. That tells me you are using a MIG or Metal inert Gas welder. 75/25 shielding gas I recommend. The only way you will know if things are going right is to look at the weld after your done.

The main thing to look for is porosity.

With a Tig I can see if there is a problem before I even add filler rod. The problem is contamination from something. I can usually tell from the color from the arc what is going on.

The first 3 rules of welding are clean, clean & clean.

Put a piece of Titanium on the stone & it will spark super bright white.

Thought I'd put this out. You can tell any steel's carbon contents buy just the numbers.

1040 steel has .40 of 1% carbon.

1050 steel has .50 of 1% carbon.

4130 steel has .30 of 1% carbon.

8620 steel has .20 of 1% carbon.

You get the picture.

You just have to put a decimal point before the last two numbers to know its carbon designation.

Cast Iron can have up to 6% carbon. The carbon atoms act as shock absorbers for compression & vibration.

1040 steel has .40 of 1% carbon.

1050 steel has .50 of 1% carbon.

4130 steel has .30 of 1% carbon.

8620 steel has .20 of 1% carbon.

You get the picture.

You just have to put a decimal point before the last two numbers to know its carbon designation.

Cast Iron can have up to 6% carbon. The carbon atoms act as shock absorbers for compression & vibration.

I like lighting old magnesium anodes from a water heater on fire. That a bright white fire.Put a piece of Titanium on the stone & it will spark super bright white.

Done, it welded up just fine with er70. While my hood was down I wondered wtf this was ground down, and the only thing I came up with is at some point this car lost it's left rear wheel and slid on the asphalt. Makes sense since the left quarter had been replaced before 1970 when the op bought it....at least all but the forward 12in or so. It's also probable the car came originally with knock-offs as they were prone to that.

Attachments

Magnesium burns white hot. I've seen a VW engine block burning at Waynoka Oklahoma State Park AKA 'Lil Sahara desert" back in the olden days.

That was a sight to see.

Years ago at the debur table. (At different Company) A group of us were de burring & sanding magnesium parts. The break bell rings. This new guy lights up a cigarette & his shirt immediately caught on fire.

He barely got that shirt of fast enough. We had these 5 gallon buckets of Magnesium extinguisher to put out Mag fires.

That was a sight to see.

Years ago at the debur table. (At different Company) A group of us were de burring & sanding magnesium parts. The break bell rings. This new guy lights up a cigarette & his shirt immediately caught on fire.

He barely got that shirt of fast enough. We had these 5 gallon buckets of Magnesium extinguisher to put out Mag fires.

I'd bet a no smoking sign went up quicker than shit!

Nope, sure didn't. That new sign cost too much money to make.I'd bet a no smoking sign went up quicker than shit!

Instead, the new rule was you couldn't smoke in the same clothes you sanded magnesium in, or your fired. End of the problem This was back in the 80's.

Yes with silicon bronze filler rod.Could it be brazed?